Reinforcement wanted: Tube reinforcement for medical technology.

Customer project for an international high-tech manufacturer.

In almost no other industry are the quality requirements as high as in medical technology. We were therefore pleased that an internationally renowned manufacturer of tubes, molded parts and micro component solutions asked us for a solution to reinforce medical tubes. As the company's innovative strength is considered unique in the industry, the challenge was particularly appealing to us.

Wanted: Reinforcement for the endless tube.

In detail, this challenge consisted of a considerable reinforcement for the endless version of the tube. The aim was for the tube to meet significantly higher burst pressure and vacuum strength requirements than the solutions used up to then, which were limited in length. In addition, the desired strength was not achieved with them.

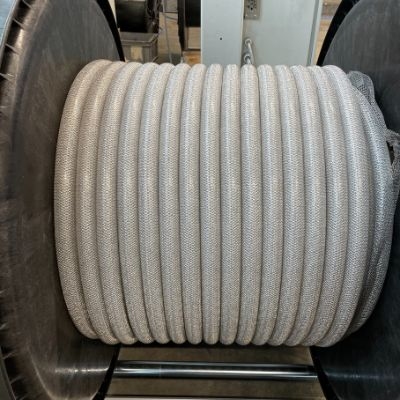

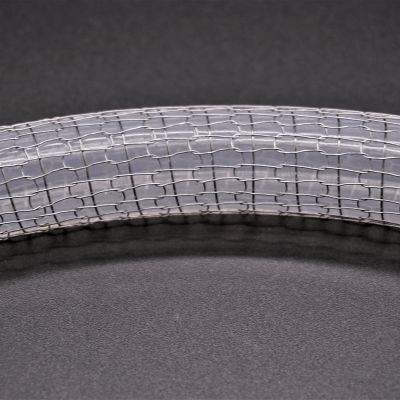

In the first solution test, we tested the pure knitting of the sample tube. However, it was not yet possible to achieve the necessary vacuum resistance of the tube. Therefore, a different solution was required. In the second approach, we first wrapped the tube with stainless steel wire of various diameters and then knitted it over continuously. With this solution, the knitted wire fixes the spiral to the tube, resulting in greater strength in terms of bursting pressure and vacuum. And this with a constant diameter.

Found: Spiral plus knitted fabric.

After several optimisation steps in the winding of the spiral and the overknitting, we had finally developed the final solution after about six weeks in close coordination with the customer. A solution that our customer is thrilled with - because it offers considerable advantages over the competition's products.